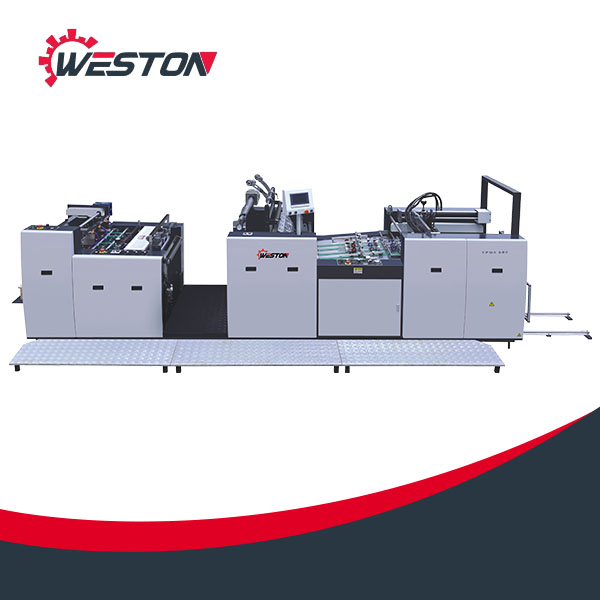

Hot Foil Stamping Machine for Paper Box and Carton Box

By:Admin

Innovative technology has always been at the forefront of the global packaging industry, and the latest addition to this ongoing trend is the new Paper Box Carton Box Hot Foil Stamping Machine. The machine, which has been developed and manufactured by a leading packaging equipment provider, is set to revolutionize the way decorative finishing is applied to paper and carton boxes, making them more visually appealing and enhancing their overall brand value.

The newly launched hot foil stamping machine is equipped with advanced features that allow for precise and high-quality stamping on a variety of materials, including paper and cardboard. This will enable packaging manufacturers to improve the aesthetic appeal of their products, making them more attractive to consumers and ultimately boosting sales.

One of the key highlights of the Paper Box Carton Box Hot Foil Stamping Machine is its versatility. It is designed to accommodate different sizes and shapes of paper and carton boxes, making it suitable for a wide range of product packaging. This flexibility ensures that packaging manufacturers can meet the diverse needs of their clients and cater to various industries, including food and beverage, cosmetics, pharmaceuticals, and more.

In addition to its versatility, the hot foil stamping machine also offers efficient and cost-effective operation. Its automated functions streamline the stamping process, reducing the need for manual labor and minimizing production costs. This makes it an ideal investment for packaging companies looking to enhance their capabilities while keeping operational expenses in check.

Furthermore, the machine is equipped with a user-friendly interface, allowing operators to easily set up and monitor the stamping process. Its intuitive controls and digital display make it accessible for workers of all skill levels, contributing to a more streamlined production workflow.

The hot foil stamping machine is also environmentally friendly, incorporating energy-efficient features that reduce power consumption and minimize its carbon footprint. This aligns with the growing trend of sustainability in the packaging industry, as companies seek to minimize their environmental impact while meeting the demands of an increasingly eco-conscious consumer base.

In line with the company’s commitment to innovation and excellence, the development of the Paper Box Carton Box Hot Foil Stamping Machine is a testament to its dedication to pushing the boundaries of technology in the packaging industry. With over [XX] years of experience in providing cutting-edge solutions for the packaging sector, the company has established itself as a trusted partner for businesses seeking to enhance their packaging capabilities.

“Our goal has always been to enable our clients to achieve exceptional results through our equipment,” said [Spokesperson], [Title] at the company. “The Paper Box Carton Box Hot Foil Stamping Machine is a testament to this commitment, offering a new level of precision and efficiency in decorative finishing for paper and carton boxes. We are proud to introduce this innovative solution to the market, and we believe it will have a significant impact on the packaging industry.”

The launch of the Paper Box Carton Box Hot Foil Stamping Machine signals a new era of possibilities for packaging manufacturers, who can now harness the power of advanced technology to elevate their products and stand out in the competitive marketplace. This latest innovation is set to make a substantial contribution to the evolution of the packaging industry, setting new standards for decorative finishing and enhancing the overall consumer experience.

Company News & Blog

High-Quality Box Gluer Machine for Efficient Folding and Sealing

The [Brand Name] Fold Box Gluer Machine, a leading product in the packaging industry, has been making waves with its innovative technology and efficient functionality. This state-of-the-art machine is designed to streamline the process of folding and gluing cardboard boxes, offering a high level of precision and consistency that is unmatched in the market.The [Brand Name] Fold Box Gluer Machine is equipped with advanced features that make it a top choice for packaging companies looking to improve their production capabilities. With its high-speed operation and customizable settings, this machine can handle a wide range of box sizes and styles, making it a versatile solution for various packaging needs.In addition to its impressive performance, the [Brand Name] Fold Box Gluer Machine is also known for its user-friendly design and easy maintenance. The intuitive controls and accessible components make it easy for operators to set up and operate the machine with minimal training, while the robust construction ensures long-lasting durability and reliability.The company behind this groundbreaking product, [Company Name], is a respected leader in the packaging industry, known for its commitment to quality and innovation. With decades of experience and a strong track record of delivering cutting-edge solutions, [Company Name] has built a solid reputation as a trusted partner for businesses looking to enhance their packaging operations.[Company Name] is dedicated to staying at the forefront of technological advancements in the industry, and the development of the [Brand Name] Fold Box Gluer Machine is a testament to this commitment. By leveraging their expertise and resources, the company has succeeded in bringing to market a product that sets new standards for efficiency and precision in box folding and gluing.In addition to the [Brand Name] Fold Box Gluer Machine, [Company Name] offers a comprehensive range of packaging machinery and equipment designed to meet the diverse needs of their clients. From box making to printing and finishing, the company provides a full suite of solutions that help businesses optimize their packaging processes and achieve superior results.The positive reception of the [Brand Name] Fold Box Gluer Machine in the market is a testament to its impact on the packaging industry. Many businesses have already adopted this innovative technology and have seen significant improvements in their production efficiency and product quality. The machine's ability to handle complex box designs with speed and accuracy has made it a game-changer for many companies seeking to stay ahead in a competitive market.Looking ahead, [Company Name] remains dedicated to pushing the boundaries of innovation and delivering solutions that drive the industry forward. With a strong focus on research and development, the company is poised to continue introducing cutting-edge products that redefine the standards of packaging technology.In conclusion, the [Brand Name] Fold Box Gluer Machine is a game-changing product that has set new benchmarks for efficiency and precision in the packaging industry. With its advanced features, user-friendly design, and the backing of a leading company like [Company Name], this machine is poised to make a lasting impact on the way businesses approach box folding and gluing. As the market continues to evolve, [Company Name] remains at the forefront of innovation, ready to deliver the next generation of solutions that will shape the future of packaging.

High-Quality Gold Foil Stamping Printer for Professional Use

Gold Foil Stamping Printer Revolutionizes Printing IndustryIn a world where first impressions matter more than ever, the importance of high-quality printing cannot be overstated. Whether it's for business cards, invitations, packaging, or marketing materials, the finishing touches can make all the difference. That's why the introduction of the Gold Foil Stamping Printer from [Company] is causing such a stir in the printing industry.[Company] is a leading provider of innovative printing solutions, with a commitment to pushing the boundaries of what is possible. With a strong focus on research and development, the company has a track record of introducing cutting-edge technologies that help their customers stand out from the crowd. The Gold Foil Stamping Printer is the latest example of this commitment to innovation.This revolutionary printer is designed to elevate printed materials to a whole new level. By utilizing advanced gold foil stamping technology, it can create stunning metallic effects that are sure to capture the attention of anyone who sees them. The printer is capable of handling a wide range of materials, from paper and cardstock to leather and plastics, making it a versatile tool for a variety of applications.One of the key features of the Gold Foil Stamping Printer is its precision. The machine is equipped with state-of-the-art sensors and actuators that ensure the foil is applied with pinpoint accuracy, resulting in crisp, clean lines and intricate detailing. This level of precision is essential for creating high-quality, professional-looking printed materials.In addition to its precision, the printer is also designed for versatility and efficiency. It can handle both short and long print runs with ease, making it an ideal solution for businesses of all sizes. The intuitive interface and user-friendly controls make it easy to operate, and the fast printing speed means that projects can be completed quickly and efficiently.The Gold Foil Stamping Printer is also environmentally friendly, utilizing eco-friendly foils and minimizing waste through its efficient design. This sustainability factor is becoming increasingly important in the printing industry, and [Company] is proud to offer a solution that meets the demands of environmentally conscious customers.The response to the Gold Foil Stamping Printer has been overwhelmingly positive. Customers who have had the opportunity to test the machine have been impressed by the quality of the results it produces and the ease of use. Many have commented on the impact that the foil stamping has had on their printed materials, transforming them from ordinary to extraordinary.In addition to the excitement from customers, industry experts have taken notice of the Gold Foil Stamping Printer. It has been recognized with several awards for its innovation and impact on the printing industry. The recognition further solidifies [Company]'s position as a leader in the field of printing technology.Looking ahead, [Company] is committed to continuing to push the boundaries of printing technology. The Gold Foil Stamping Printer is just the beginning of a new era of innovation, and the company has several other exciting projects in the pipeline. With a focus on meeting the evolving needs of their customers and the industry as a whole, [Company] is poised to remain at the forefront of the printing industry for years to come.In conclusion, the introduction of the Gold Foil Stamping Printer from [Company] represents a significant leap forward for the printing industry. By combining advanced technology with precision, versatility, and sustainability, the company has created a solution that is sure to make a lasting impact. As businesses and individuals continue to prioritize high-quality printing, the Gold Foil Stamping Printer is positioned to become an essential tool for those who want to stand out from the crowd.

Harnessing the Power of Film Surface Hot Press Lines for Effective Production

In the ever-expanding world of manufacturing, there are certain pieces of equipment that are essential for maintaining high production standards and manufacturing accuracy. One of these machines is the Film Surface Hot Press Line, a machine that is commonly used in the production of modern-day laminates. This machine is offered by several manufacturers, but one that stands out is {} which is known for its superior products and services.The Film Surface Hot Press Line is a machine that is designed to laminate a specific substrate with a decorative laminate sheet, creating a durable and visually appealing surface. The process is simple, yet effective, and involves the use of heat, pressure, and adhesive to bond the two materials together.The hot press line consists of several key components, including the loading and unloading station, the preheating station, the positioning system, the hot pressing station, and the cooling station. Each component plays a vital role in the successful operation of the hot press line.The loading and unloading station is where the operator loads the substrate and decorative laminate sheets onto the machine. The preheating station is used to warm up the materials, making them easier to handle in subsequent stations.The positioning system is where the operator precisely positions the substrate and laminate sheets to ensure that they are aligned correctly. The hot pressing station is where the actual bonding process takes place, as the substrate and laminate sheets are exposed to heat and pressure to create a seamless and durable surface. Finally, the cooling station is where the newly laminated product is cooled down to its final state.{} is one of the leading manufacturers of the Film Surface Hot Press Line, known for its innovative products and state-of-the-art technology. The company has been in the business of manufacturing laminating machines for over 20 years, and has built a reputation for excellence and quality.In addition to manufacturing high-quality machinery, {} also provides exceptional customer service and support. The company's team of experienced engineers and technicians are available to assist customers with any technical questions or issues that may arise.Furthermore, the {} hot press line is designed to be versatile and customizable, with several optional features that can be added to meet the specific needs of each customer. One of the key benefits of the machine is its ease of use, making it an ideal choice for both small-scale and large-scale laminating operations.Finally, it is notable that {} hot press line is designed with a focus on safety, incorporating several safety features to protect both the operator and the machine. These features include automatic shutdown in case of emergency and safety sensors to prevent accidents.In conclusion, the Film Surface Hot Press Line is an essential machine in the manufacturing of modern-day laminates, and {} is one of the leading manufacturers of this machine. With its innovative products, exceptional customer service, and commitment to safety, {} is a top choice for businesses looking for high-quality laminating machinery. Whether for small-scale or large-scale operations, the {} hot press line is a versatile and customizable machine that can meet the unique needs of any customer.

Hot Foil Stamping Machine for Paper Box and Carton Box

Paper Box Carton Box Hot Foil Stamping Machine Revolutionizes Packaging IndustryInnovative technology has always been at the forefront of the global packaging industry, and the latest addition to this ongoing trend is the new Paper Box Carton Box Hot Foil Stamping Machine. The machine, which has been developed and manufactured by a leading packaging equipment provider, is set to revolutionize the way decorative finishing is applied to paper and carton boxes, making them more visually appealing and enhancing their overall brand value.The newly launched hot foil stamping machine is equipped with advanced features that allow for precise and high-quality stamping on a variety of materials, including paper and cardboard. This will enable packaging manufacturers to improve the aesthetic appeal of their products, making them more attractive to consumers and ultimately boosting sales.One of the key highlights of the Paper Box Carton Box Hot Foil Stamping Machine is its versatility. It is designed to accommodate different sizes and shapes of paper and carton boxes, making it suitable for a wide range of product packaging. This flexibility ensures that packaging manufacturers can meet the diverse needs of their clients and cater to various industries, including food and beverage, cosmetics, pharmaceuticals, and more.In addition to its versatility, the hot foil stamping machine also offers efficient and cost-effective operation. Its automated functions streamline the stamping process, reducing the need for manual labor and minimizing production costs. This makes it an ideal investment for packaging companies looking to enhance their capabilities while keeping operational expenses in check.Furthermore, the machine is equipped with a user-friendly interface, allowing operators to easily set up and monitor the stamping process. Its intuitive controls and digital display make it accessible for workers of all skill levels, contributing to a more streamlined production workflow.The hot foil stamping machine is also environmentally friendly, incorporating energy-efficient features that reduce power consumption and minimize its carbon footprint. This aligns with the growing trend of sustainability in the packaging industry, as companies seek to minimize their environmental impact while meeting the demands of an increasingly eco-conscious consumer base.In line with the company’s commitment to innovation and excellence, the development of the Paper Box Carton Box Hot Foil Stamping Machine is a testament to its dedication to pushing the boundaries of technology in the packaging industry. With over [XX] years of experience in providing cutting-edge solutions for the packaging sector, the company has established itself as a trusted partner for businesses seeking to enhance their packaging capabilities.“Our goal has always been to enable our clients to achieve exceptional results through our equipment,” said [Spokesperson], [Title] at the company. “The Paper Box Carton Box Hot Foil Stamping Machine is a testament to this commitment, offering a new level of precision and efficiency in decorative finishing for paper and carton boxes. We are proud to introduce this innovative solution to the market, and we believe it will have a significant impact on the packaging industry.”The launch of the Paper Box Carton Box Hot Foil Stamping Machine signals a new era of possibilities for packaging manufacturers, who can now harness the power of advanced technology to elevate their products and stand out in the competitive marketplace. This latest innovation is set to make a substantial contribution to the evolution of the packaging industry, setting new standards for decorative finishing and enhancing the overall consumer experience.

New Hydrophobic Coating Promises to Keep Surfaces Dry for Longer

Coating Industry Looks to Revolutionize Productivity and SustainabilityCoatings are a critical aspect of modern manufacturing, whether it's for industrial equipment, consumer goods or vehicles. They play an essential role in protecting surfaces, enhancing their aesthetics, and improving their performance. A new coating product is set to revolutionize the coating industry with a blend of cutting-edge technologies.The introduction of NextGen Coating Solution, a new product from a leading coating company, promises to change the game in the coating industry. This innovative solution combines the latest breakthroughs in nanotechnology and surface chemistry to create a new generation of high-performance coatings.NextGen Coating Solution provides a range of benefits that far exceed traditional coatings. Its unique composition gives it superior adhesion and durability, making it ideal for high-wear applications. The product is designed to withstand harsh environments, including exposure to chemicals, sunlight, and extreme temperatures.The new coating also has excellent water and oil repellency properties. This makes it particularly useful in applications where maintaining a clean and hygienic surface is essential. Additionally, the product has exceptional weathering properties, ensuring that surfaces remain looking new for longer.One of the most significant advantages of NextGen Coating Solution is its environmental impact. The solution is formulated to be VOC-free, which makes it safer for application and handling. The product is also biodegradable, allowing for easy disposal and reducing the impact on the environment.The coating industry has been facing increasing scrutiny over its environmental impact, with many companies looking for ways to reduce their carbon footprint. NextGen Coating Solution offers a sustainable alternative that addresses this concern while still providing superior performance.The new coating product is designed to be compatible with a wide range of materials, including metals, plastics, and ceramics. This versatility makes it well-suited for various industries, ranging from automotive and aerospace to microelectronics and consumer electronics. It can be used for applications such as corrosion protection, abrasion resistance, and surface enhancement.The benefits of NextGen Coating Solution don't stop at surface protection. The product is also designed to improve manufacturing productivity. Its ability to bond to surfaces more effectively than traditional coatings leads to fewer application failures, reducing the need for costly rework. This, in turn, improves efficiency, reducing production costs.In addition to its higher durability, NextGen Coating Solution also provides superior surface aesthetics. The solution is available in a range of colors, allowing manufacturers to choose the best option for their product design. The product is also formulated to provide a smooth and consistent finish, improving the overall appearance of surfaces.Overall, the introduction of NextGen Coating Solution is set to revolutionize the coating industry. The product's superior performance, sustainability, and versatility make it an attractive option for companies looking to improve their products while reducing their impact on the environment.The company behind the innovative product, one of the leading players in the coating industry, is committed to innovation and sustainability. They aim to offer customers the latest technological advancements, combined with a commitment to environmental responsibility.The company has invested heavily in research and development to create products that deliver superior performance while reducing their environmental impact. NextGen Coating Solution is an excellent example of their commitment to innovation and sustainability.The new coating product's launch marks an exciting time in the coating industry, as companies look for ways to improve their products' sustainability and performance. NextGen Coating Solution is set to play a vital role in this evolution, providing a sustainable and high-performance alternative to traditional coatings.In conclusion, NextGen Coating Solution is a significant milestone in the coating industry. Its unique composition offers a range of benefits that far exceed traditional coatings, including superior durability, environmental sustainability, and improved aesthetics. The product's versatility makes it well-suited for various industries, providing an attractive option for manufacturers looking to enhance their products' performance while reducing their environmental impact.

Advanced UV Cold Foil Machine for Enhanced Printing Results

UV Cold Foil Machine Revolutionizes Foil Printing in the Packaging IndustryThe packaging industry is constantly evolving and innovating to meet the demands of an ever-changing market. One such innovation that is revolutionizing the industry is the UV Cold Foil Machine.The UV Cold Foil Machine, developed by a leading manufacturer in the packaging industry, is a state-of-the-art piece of equipment that has transformed the way foil printing is done. This machine uses a unique process that allows for the application of foil to packaging materials without the need for heat, making it an environmentally friendly and cost-effective solution for packaging design.The UV Cold Foil Machine offers several advantages over traditional foil printing methods. Firstly, it eliminates the need for hot stamping, which often requires significant energy consumption and can result in a higher carbon footprint. By using UV curing technology, the machine is able to apply foil to packaging materials without the use of heat, making it a greener alternative.Additionally, the UV Cold Foil Machine is capable of producing high-quality, intricate designs with precision and accuracy. This level of detail is difficult to achieve with traditional foil printing methods, making the machine a game-changer for packaging designers and manufacturers.Furthermore, the UV Cold Foil Machine is compatible with a wide range of packaging materials, including paper, cardboard, and plastic. This versatility makes it an ideal solution for a variety of packaging applications, from food and beverage to beauty and cosmetics products.The company behind the UV Cold Foil Machine has a long-standing reputation for delivering cutting-edge packaging solutions to its clients. With a focus on innovation and sustainability, the company is committed to developing products that not only meet the needs of the market but also minimize environmental impact.In addition to the UV Cold Foil Machine, the company offers a range of other packaging machinery and equipment to support the diverse needs of its clients. From printing and labeling machines to packaging automation solutions, the company is a one-stop-shop for all packaging needs.With a global presence and a strong emphasis on customer satisfaction, the company has established itself as a leader in the packaging industry. Its dedication to quality, innovation, and sustainability has earned it the trust and loyalty of numerous clients around the world.The introduction of the UV Cold Foil Machine is a testament to the company's commitment to pushing the boundaries of packaging technology. By offering a solution that not only improves the efficiency and quality of foil printing but also reduces environmental impact, the company has once again proven itself as an industry leader.In conclusion, the UV Cold Foil Machine has transformed the way foil printing is done in the packaging industry. With its innovative technology, environmental sustainability, and unparalleled precision, it has set a new standard for packaging design and manufacturing. As the industry continues to evolve, the UV Cold Foil Machine is sure to play a key role in shaping the future of packaging.

Enhance Document Protection and Add a Glossy Finish with Laminating Machine Type UV Coater

Title: Innovative Laminating Machine Type UV Coater Revolutionizes Surface Enhancement ProcessesIntroduction:In the ever-evolving world of printing and surface enhancement technology, companies constantly strive to enhance their products with innovative solutions. One particular market disruptor has emerged in the form of an advanced Laminating Machine Type UV Coater, developed by a leading industry player. This cutting-edge machine offers a range of benefits and improvements to existing surface coating processes, meeting the demands of modern consumers who seek high-quality and visually appealing products. This article will delve into the features, advantages, and impact of this ground-breaking UV Coater.I. The Evolution of Surface Enhancement Technology:In recent years, surface enhancement techniques, such as lamination and UV coating, have gained significant popularity across various industries. They not only protect printed materials from wear and tear but also significantly enhance their visual appeal. Traditional lamination processes involved heat-sealing a plastic film onto the surface; however, advancements in technology have led to the development of the Laminating Machine Type UV Coater.II. Features of the Laminating Machine Type UV Coater:This innovative UV Coater combines state-of-the-art technology with a user-friendly interface, making it highly versatile and efficient. It eliminates the need for traditional laminating films and revolutionizes the bonding process through the application of ultraviolet (UV) light. Some key features of this machine include:a) Instant Curing: The UV Coater utilizes UV light to cure the coating instantly, ensuring faster production times and increased efficiency.b) Environmentally Friendly: Unlike traditional laminating processes, this coater is solvent-free, reducing environmental impacts and making it a more sustainable choice.c) Versatile Coating Options: The UV Coater offers a range of coating options, including gloss, matte, and satin finishes, catering to diverse consumer preferences.d) Advanced Control System: Its intuitive control panel allows operators to adjust parameters easily, ensuring precise and consistent coating applications.III. Advantages and Impact on Businesses:By adopting the Laminating Machine Type UV Coater, businesses can experience several advantages that enhance their overall workflow and product quality.a) Improved Product Aesthetics: The UV Coater enhances printed materials by providing a premium, vibrant, and eco-friendly finish, elevating the visual appeal of products and attracting consumers.b) Enhanced Durability: The UV coating provides an additional layer of protection, making printed materials more resistant to water, scratches, and UV fading.c) Increased Productivity: With instant curing capabilities, the UV Coater significantly reduces lead times, allowing for faster production and quicker delivery to clients.d) Cost-Effectiveness: The solvent-free nature of this coater eliminates the need for expensive film rolls and reduces operating costs in the long run.IV. Market Potential and Company Expertise:With its commitment to innovation and focus on meeting customer expectations, the developer company behind the Laminating Machine Type UV Coater is a renowned industry leader. With years of experience, they have unparalleled expertise in developing advanced coating solutions. This UV Coater showcases their understanding of emerging market trends and their ability to deliver groundbreaking products that revolutionize surface enhancement processes.V. Conclusion:The introduction of the Laminating Machine Type UV Coater has introduced a new era in surface enhancement technology, providing businesses with a game-changing solution to elevate the aesthetic appeal, durability, and overall quality of their products. By adopting this advanced UV Coater, companies can enhance their competitiveness in the market, reduce costs, and deliver superior products to their customers. With its versatile features and sustainable practices, this innovation sets a new industry benchmark and signifies the ongoing advancements in the field of surface coating technologies.

Unlock Efficiency with the Innovative Lock-Bottom Type Semi-Auto Folder Gluer

Title: Innovative Lock-Bottom Type Semi-Auto Folder Gluer Revolutionizes Packaging IndustryIntroduction: The packaging industry is constantly evolving to meet the growing demands of businesses and consumers. As e-commerce continues to gain popularity, the need for efficient and secure packaging solutions has become paramount. In response to this demand, manufacturing company {} has introduced an innovative Lock-Bottom Type Semi-Auto Folder Gluer that promises to revolutionize the packaging process. With cutting-edge technology and enhanced functionality, this new gluer is set to redefine efficiency and convenience in the industry.I. Overview of the Lock-Bottom Type Semi-Auto Folder GluerThe {} Lock-Bottom Type Semi-Auto Folder Gluer brings forth a wide range of features designed to streamline packaging operations. This state-of-the-art machinery automates the folder gluer process, simplifying and accelerating the production of lock-bottom type boxes. The gluer seamlessly consolidates the folding, gluing, and bottom locking processes, significantly reducing assembly time.II. Enhanced Efficiency and ConvenienceThe Lock-Bottom Type Semi-Auto Folder Gluer is equipped with advanced technology that ensures precise folding and accurate gluing, minimizing errors and waste in the production line. By automating the process, it eliminates the need for time-consuming and labor-intensive manual folding and gluing. As a result, businesses can achieve higher production rates and meet tight delivery deadlines, enhancing customer satisfaction.III. Versatile Application and AdaptabilityOne of the standout features of this gluer is its ability to handle a variety of box sizes and thicknesses. It can effortlessly accommodate boxes ranging from small-sized jewelry packages to large-sized shoeboxes, offering versatility for different packaging requirements. The adjustable settings allow for quick and easy customization, enabling businesses to adapt to changing market demands seamlessly.IV. Durability and Minimal MaintenanceThe Lock-Bottom Type Semi-Auto Folder Gluer is built with high-quality materials and components that ensure durability and longevity. Its robust structure guarantees stability during operation, reducing the risk of malfunctions. Additionally, the gluer requires minimal maintenance, saving valuable time and resources for businesses.V. Enhanced Worker Safety and ErgonomicsConcern for worker safety is paramount in any manufacturing industry. The Lock-Bottom Type Semi-Auto Folder Gluer incorporates safety features to protect operators from potential hazards during operation. The ergonomic design minimizes strain and fatigue, providing a comfortable working environment. By prioritizing worker safety, businesses can boost productivity while ensuring the well-being of their employees.VI. Cost-Efficiency and Return on InvestmentInvesting in the Lock-Bottom Type Semi-Auto Folder Gluer can yield long-term cost savings for businesses. The automation of the packaging process leads to reduced labor costs and increased operational efficiency. By streamlining production and minimizing material waste, businesses can optimize resources and maximize profitability. Furthermore, the durability of the gluer ensures longevity, making it a sound investment for long-term usage.Conclusion:{}'s Lock-Bottom Type Semi-Auto Folder Gluer represents a significant leap forward in streamlining the packaging process. Its advanced features, versatility, and adaptability make it an ideal solution for businesses seeking to enhance efficiency and meet growing consumer demands. With enhanced worker safety, minimal maintenance, and cost savings, this gluer holds tremendous potential for reshaping the packaging industry. As businesses worldwide continually strive to stay ahead in an increasingly competitive market, the Lock-Bottom Type Semi-Auto Folder Gluer proves to be a game-changer in the pursuit of operational excellence.

New Breakthrough in the World of Automatic Screen Printing Machines Unveiled

Title: Advanced Automatic Screen Printing Machine Revolutionizes Printing IndustryIntroduction:The printing industry has seen numerous advancements over the years, with technological innovations continuously enhancing productivity and efficiency. One such breakthrough is the introduction of the revolutionary Automatic Screen Printing Machine by a leading player in the industry. This cutting-edge machine, which excels in performance and versatility, is set to redefine the standards of printing.Advanced Features of the Automatic Screen Printing Machine:The Automatic Screen Printing Machine offers a host of advanced features that make it an indispensable asset for businesses in the printing sector. With high-speed operation, exceptional print quality, and unrivaled flexibility, this machine is designed to meet the evolving needs of the industry.1. High-Speed Operation:Equipped with state-of-the-art technology, the Automatic Screen Printing Machine boasts an impressive speed, allowing it to quickly and efficiently produce large volumes of high-quality prints. Its superior performance ensures reduced lead times, enabling businesses to meet tight deadlines while maintaining optimal quality.2. Exceptional Print Quality:Precision is of utmost importance in the printing industry, and this machine delivers precise and consistent results every time. The Automatic Screen Printing Machine utilizes advanced color matching and registration systems, guaranteeing exceptional print quality regardless of the complexity or intricacy of the design. This ensures that the final product meets or exceeds customer expectations.3. Versatility:The versatility of the Automatic Screen Printing Machine sets it apart from its competitors. It can be easily adjusted to accommodate various printing substrates, including textiles, ceramics, plastics, glass, and many more. This flexibility allows businesses to explore diverse markets and cater to a wide range of customer requirements with a single machine.Company XYZ Drives Innovation:Leading the charge in printing technology, Company XYZ has brought forth the Automatic Screen Printing Machine, showcasing its commitment to revolutionizing the industry. With decades of experience and a customer-focused approach, Company XYZ has consistently developed and manufactured cutting-edge printing solutions for businesses worldwide.Established with a vision to deliver excellence, Company XYZ has earned a solid reputation for creating machines that redefine industry standards. They collaborate with industry experts to gather insights into market demands, allowing them to develop products that are not only innovative but also address the evolving needs of their customers.By leveraging their extensive research and development capabilities, Company XYZ has successfully incorporated the latest advancements in technology into the Automatic Screen Printing Machine. This dedication to innovation ensures that their machines remain at the forefront of the industry, providing businesses with a competitive edge.Conclusion:The introduction of the Automatic Screen Printing Machine marks a significant milestone in the printing industry. Its exceptional performance, high-speed operation, and versatility make it a game-changer for businesses seeking to enhance their printing capabilities. Company XYZ's commitment to innovation and customer satisfaction has paved the way for this groundbreaking technology, positioning them as a trailblazer in the industry.With the Automatic Screen Printing Machine, the future of printing has arrived, promising improved efficiency, reduced lead times, and top-notch print quality. Businesses that embrace this cutting-edge technology can expect to elevate their productivity and gain a competitive advantage in an ever-evolving market.