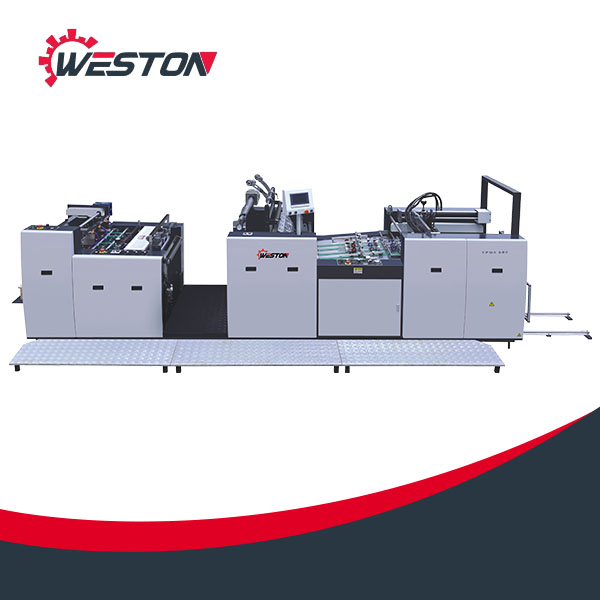

Impressive IR Dryer Tunnel and Paper Stacking Machine Revolutionize Industry Standards

By:Admin

The IR dryer tunnel is a piece of equipment used to dry materials after they have been printed or coated. It uses infrared radiation to rapidly heat the material and evaporate the solvents, leaving a dry surface. This is particularly useful in industries such as packaging and printing, where high-speed printing or coating is required. The dryer tunnel can reduce the time needed to dry materials by up to 80%, greatly improving production efficiency.

The paper stacking machine is another useful piece of equipment for manufacturers. It is used to stack sheets of paper or other materials into neat piles, ready for packaging or further processing. This may seem like a simple task, but it is one that can be time-consuming and prone to errors if done manually. The paper stacking machine can handle large volumes of material and stack them quickly and accurately, reducing the need for manual labor and improving production times.

One company at the forefront of manufacturing technology is a leading manufacturer of these types of equipment. They have years of experience in the field and are dedicated to providing high-quality solutions to their clients. Their IR dryer tunnel and paper stacking machine are just two of the many pieces of equipment they offer, all designed to improve productivity and efficiency in manufacturing.

The company has a team of highly skilled engineers and technicians who are constantly working to improve their products. They use the latest technology and materials to create reliable, durable equipment that can withstand the demands of a busy manufacturing environment. Their commitment to quality is evident in their ISO 9001 certification, which ensures that their products meet the highest standards of performance and safety.

Their IR dryer tunnel and paper stacking machine are designed to be user-friendly and easy to operate. They can be customized to meet the specific needs of each client, ensuring that they get the most out of their equipment. The company also provides comprehensive training and technical support to their clients, ensuring that they are able to make full use of their equipment and maximize their productivity.

The IR dryer tunnel and paper stacking machine are just two examples of the innovative solutions offered by this leading manufacturer. They also offer a range of other equipment, including laminators, embossing machines, and label printing machines. All of their products are designed to meet the needs of a variety of industries, including packaging, printing, and textiles.

In conclusion, the IR dryer tunnel and paper stacking machine represent a significant step forward in manufacturing technology. They offer a solution to the challenges faced by manufacturers, improving productivity and reducing production times. The leading manufacturer of this equipment has a track record of providing high-quality, reliable solutions to their clients, and is dedicated to continuous improvement. With their focus on quality, innovation, and customer satisfaction, this company is sure to remain at the forefront of manufacturing technology for years to come.

Company News & Blog

Unlock Efficiency with the Innovative Lock-Bottom Type Semi-Auto Folder Gluer

Title: Innovative Lock-Bottom Type Semi-Auto Folder Gluer Revolutionizes Packaging IndustryIntroduction: The packaging industry is constantly evolving to meet the growing demands of businesses and consumers. As e-commerce continues to gain popularity, the need for efficient and secure packaging solutions has become paramount. In response to this demand, manufacturing company {} has introduced an innovative Lock-Bottom Type Semi-Auto Folder Gluer that promises to revolutionize the packaging process. With cutting-edge technology and enhanced functionality, this new gluer is set to redefine efficiency and convenience in the industry.I. Overview of the Lock-Bottom Type Semi-Auto Folder GluerThe {} Lock-Bottom Type Semi-Auto Folder Gluer brings forth a wide range of features designed to streamline packaging operations. This state-of-the-art machinery automates the folder gluer process, simplifying and accelerating the production of lock-bottom type boxes. The gluer seamlessly consolidates the folding, gluing, and bottom locking processes, significantly reducing assembly time.II. Enhanced Efficiency and ConvenienceThe Lock-Bottom Type Semi-Auto Folder Gluer is equipped with advanced technology that ensures precise folding and accurate gluing, minimizing errors and waste in the production line. By automating the process, it eliminates the need for time-consuming and labor-intensive manual folding and gluing. As a result, businesses can achieve higher production rates and meet tight delivery deadlines, enhancing customer satisfaction.III. Versatile Application and AdaptabilityOne of the standout features of this gluer is its ability to handle a variety of box sizes and thicknesses. It can effortlessly accommodate boxes ranging from small-sized jewelry packages to large-sized shoeboxes, offering versatility for different packaging requirements. The adjustable settings allow for quick and easy customization, enabling businesses to adapt to changing market demands seamlessly.IV. Durability and Minimal MaintenanceThe Lock-Bottom Type Semi-Auto Folder Gluer is built with high-quality materials and components that ensure durability and longevity. Its robust structure guarantees stability during operation, reducing the risk of malfunctions. Additionally, the gluer requires minimal maintenance, saving valuable time and resources for businesses.V. Enhanced Worker Safety and ErgonomicsConcern for worker safety is paramount in any manufacturing industry. The Lock-Bottom Type Semi-Auto Folder Gluer incorporates safety features to protect operators from potential hazards during operation. The ergonomic design minimizes strain and fatigue, providing a comfortable working environment. By prioritizing worker safety, businesses can boost productivity while ensuring the well-being of their employees.VI. Cost-Efficiency and Return on InvestmentInvesting in the Lock-Bottom Type Semi-Auto Folder Gluer can yield long-term cost savings for businesses. The automation of the packaging process leads to reduced labor costs and increased operational efficiency. By streamlining production and minimizing material waste, businesses can optimize resources and maximize profitability. Furthermore, the durability of the gluer ensures longevity, making it a sound investment for long-term usage.Conclusion:{}'s Lock-Bottom Type Semi-Auto Folder Gluer represents a significant leap forward in streamlining the packaging process. Its advanced features, versatility, and adaptability make it an ideal solution for businesses seeking to enhance efficiency and meet growing consumer demands. With enhanced worker safety, minimal maintenance, and cost savings, this gluer holds tremendous potential for reshaping the packaging industry. As businesses worldwide continually strive to stay ahead in an increasingly competitive market, the Lock-Bottom Type Semi-Auto Folder Gluer proves to be a game-changer in the pursuit of operational excellence.

New Automated Machine Streamlines Box Production Process

The packaging industry has evolved significantly over the last few years with smart automation taking over the manual processes. The Box Forming Machine is one such innovation that has brought about a revolution in the packaging industry. The machine, which is designed to produce boxes automatically, has dramatically increased production efficiency and reduced labor costs.As the demand for lightweight, efficient, and eco-friendly packaging continues to grow, the Box Forming Machine has become a game-changer for packaging companies worldwide. This next-generation machine has leveraged advanced robotic technology to create well-structured boxes within a matter of minutes.“With the Box Forming Machine, we have experienced a massive improvement in the quality and efficiency of our packaging process. Our production has increased several times over, and we're now able to deliver a far more streamlined and improved service to our clients,” said a company spokesperson.This machine has helped businesses save significant time and money by streamlining their workflow, reducing manual labor, and subsequently, errors. It is especially useful for businesses that need to produce a high volume of packages within a short amount of time. The Box Forming Machine is automated and produces several boxes simultaneously, significantly boosting production while reducing errors in the process.Our company specializes in the production of Box Forming Machines, and we offer fully automated systems that cater to the unique requirements of our clients. Our main objective is to provide high-performance, cost-effective, and eco-friendly packaging equipment that enables our clients to achieve their production objectives. We are dedicated to innovation, and we continuously make improvements to our machines to meet the needs of the rapidly changing technology landscape.“We are proud of our commitment to sustainability and conscious manufacturing. Our machines are designed to optimize energy efficiency while reducing material waste and minimizing our carbon footprint,” said the company spokesperson.Our Box Forming Machines are suitable for a wide range of industries, including food, beverage, pharmaceuticals, cosmetics, consumer electronics, and many more. We tailor our machines based on the size, shape, and other specifications our clients' requirements. Our team of experts will work with your team throughout the installation and training process to ensure a seamless transition into your workflow.“Our clients appreciate our personalized approach and commitment to delivering the highest quality machines that meet their unique needs,” added the spokesperson.With the rapid growth of e-commerce, the demand for efficient and sustainable packaging solutions is at an all-time high. The Box Forming Machine has become an indispensable tool for businesses looking to stay ahead of the competition. It is an excellent investment that offers long-term benefits, including increased productivity, lower labor costs, and improved quality control.In conclusion, the Box Forming Machine has revolutionized the packaging industry by significantly reducing production time and costs while improving quality and sustainability. Our company is committed to innovative, sustainable, and cost-effective packaging solutions, and we’re thrilled to continue developing next-generation machines that serve the needs of our clients.

How Extrusion Machines are Used in Manufacturing Processes

In today’s world of manufacturing and production, efficiency is everything. With the demand for high output and quick turnaround, companies are constantly pushing the boundaries of automation and technology to achieve their goals. One of the most important aspects of this process is the use of extrusion machines. These machines are designed to offer high-quality output at a faster rate than traditional production methods, which is why they are so popular in many different industries.The (remove brand name) Extrusion Machine is one of the most advanced machines available in the market today. It has been designed to cater to the needs of various industries including packaging, food and beverage, automotive, construction and many others. The machine incorporates the most advanced technologies to ensure that it delivers consistent and high-quality extrusion outputs.One of the noteworthy features of this machine is that it is highly customizable. This means that it can be designed and built to meet the unique requirements of each client, depending on the product being manufactured. Everything from the machine size, output rate, to the type of raw material being used can be tailored to meet specific needs. This results in a more efficient and cost-effective production process, leading to greater profitability.The advanced control system of the (remove brand name) Extrusion Machine ensures that the extrusion process is consistent and precise. The machine has the ability to self-diagnose and calibrate itself which ensures a minimal amount of downtime during production. This also means that the company can reduce the number of employees required during the process, leading to a further reduction in operational costs.The machine’s extrusion screw is another critical component that sets it apart from other machines. The screw is designed to provide a high melting and mixing capability that results in a homogenous output. This leads to improved product quality while reducing the chances of defects and waste. The extrusion screw’s high torque, combined with a temperature control system, ensures that the output is of the highest possible quality.The (remove brand name) Extrusion Machine also features an advanced heating and cooling system. This system ensures that the temperature of the product being manufactured is maintained at a consistent level, which is essential in ensuring a high-quality output. The system is designed to offer precision temperature control which also leads to better energy efficiency and a reduced carbon footprint.Another noteworthy feature of the (remove brand name) Extrusion Machine is its ease of operation. The machine’s user-friendly interface allows operators to quickly and easily adjust various parameters such as output rate, raw material density, and temperature. The interface is easy to navigate and clearly displays all relevant information regarding the production process.Given the array of features and functionalities, it is no surprise that this machine is highly sought after in the market. The (remove brand name) Extrusion Machine has been designed and manufactured by a company that has been in the industry for many years. The company has developed a reputation for producing high-quality equipment that delivers results in an efficient and cost-effective manner.In conclusion, the (remove brand name) Extrusion Machine is a cutting-edge piece of technology designed to cater to the ever-increasing demand for efficiency in manufacturing. The machine offers a range of advanced features that ensure consistent, high-quality outputs that meet the unique requirements of each client. Moreover, the machine is highly customizable, user-friendly, and energy efficient. With such impressive features, it is no surprise that the (remove brand name) Extrusion Machine is one of the most sought-after machines in the market today.

Innovative Double Sheets Folder Gluer Machine for Enhanced Productivity

Double Sheets Folder Gluer Machine: Streamlining Production and Increasing Efficiency for Manufacturing IndustryWith the increasing demand for fast and reliable production machinery, the need for advanced equipment for the manufacturing industry is on the rise. One such machine making waves in the industry is the Double Sheets Folder Gluer Machine, which has been praised for its unique capacity to improve production efficiency. What is a Double Sheets Folder Gluer Machine? A Double Sheets Folder Gluer Machine is an advanced folding and gluing machine that is designed to streamline the process of producing paper cartons, boxes, and packaging products for the food and beverage industry. It is a machine that has garnered widespread recognition due to its high precision, exceptional design, and efficiency in the production process. The machine comes with an impressive array of features, including the ability to automatically stick and fold corrugated paper boards and other flat-packaging products, making it a popular choice for businesses that aim to improve their packaging line. The addition of the double-sheet feeding function means that the machine is perfect for the production of box lids, carton bottoms, and inner support plates. This feature has allowed businesses to produce products that are not only of high quality but also cost-efficient. The significance of the Double Sheets Folder Gluer Machine in the manufacturing industry cannot be overstated. Its ability to streamline the production process has reduced the reliance on manual labour, freeing up workers for more skilled and technical tasks while reducing the risk of human error. The machine has also enhanced the quality and precision of the production process while increasing the speed of production. The Companies behind the Double Sheets Folder Gluer Machine There are various companies globally that specialize in the production and development of the Double Sheets Folder Gluer Machine. However, one such company stands out from the rest, offering quality machines renowned for their durability and exceptional performance. The company has been in operation for over a decade, providing clients with innovative solutions to manufacturing challenges. The company prides itself on providing world-class machinery and exceptional customer service. They are dedicated to designing, producing, and distributing advanced equipment that surpasses industry standards, ensuring the highest quality of the output. Theirs is a commitment to delivering products that will improve their clients' production line, increasing efficiency, and reducing costs while maintaining the highest level of quality. The company is renowned for providing clients from the manufacturing industry with customized solutions that meet their specific production requirements. Their machines come with an array of unique features, allowing for customization to adapt to individual client needs. They offer their assembly and installation services, ensuring that their clients' machines are up and running efficiently and effectively. Conclusion The Double Sheets Folder Gluer Machine has transformed the manufacturing industry, offering businesses a unique opportunity to streamline production while increasing efficiency and reducing costs. The machine's automation and precise folding and gluing function have eliminated the need for manual labour while ensuring that the quality of production is maintained. The machine has improved the speed and precision of the production process, making it an essential tool for any business looking to enhance its production line. With the increasing demand for high-quality machinery that can meet unique and specific production needs, the need for customized solutions is also on the rise. The company behind the Double Sheets Folder Gluer Machine has recognized this need and is dedicated to providing its clients with customized solutions that meet their production line requirements. As the manufacturing industry continues to grow, there is no doubt that the Double Sheets Folder Gluer Machine will remain an essential tool in enhancing production line efficiency and maintaining the highest levels of quality.

Innovative Lock Bottom Folder Gluer Redefining Efficiency and Convenience in Packaging

Title: Innovative Lock Bottom Folder Gluer Revolutionizes Packaging IndustryIntroduction:In today's fast-paced world, the manufacturing industry is constantly evolving to meet the ever-increasing demands of consumers. The packaging sector, in particular, plays a vital role in ensuring the safety and efficiency of products during transportation and storage. The lock bottom folder gluer machines have emerged as a game-changer, offering enhanced productivity, versatility, and cost-efficiency to packaging companies. This article will shed light on the revolutionary features of the lock bottom folder gluer machine developed by an industry-leading company, revolutionizing the packaging industry.Enhanced Productivity:Lock bottom folder gluer machines eliminate the tedious and time-consuming manual assembly of packaging boxes. By automating the folding and gluing process, they dramatically increase productivity. These cutting-edge machines can handle a wide range of box sizes and formats, accommodating various packaging needs. With efficient gluing and quick drying capabilities, the lock bottom folder gluer machine ensures that boxes are securely sealed, maintaining the integrity of the package contents. This increased productivity reduces downtime and allows packaging companies to meet tight production deadlines efficiently.Versatility in Design:One of the standout features of the lock bottom folder gluer machine is its ability to create versatile box designs. The machine effortlessly handles different folding styles, including straight-line, crash-lock bottom, four-corner, six-corner, and more. This flexibility enables packaging companies to cater to the diverse packaging requirements of various industries, such as food and beverages, cosmetics, pharmaceuticals, and e-commerce. With customizable options, such as adjustable folding mechanisms and glue application areas, the lock bottom folder gluer machine delivers flawless finished products, fulfilling the unique design preferences of customers.Cost-Efficiency:Implementing the lock bottom folder gluer machine in the production process offers significant cost savings to packaging companies. The elimination of manual labor reduces dependence on human resources, saving on labor costs and increasing overall operational efficiency. Additionally, the accuracy and precision of the lock bottom folder gluer machine minimize material wastage by ensuring consistent folds and glue application on each box. This reduction in rejects and rework significantly lowers production costs, leading to higher profitability for packaging businesses.Advanced Technology Integration:The lock bottom folder gluer machine incorporates advanced technologies to streamline the packaging process further. State-of-the-art sensors and control systems ensure precise box alignment, accurate creasing, and optimal glue application. This precision guarantees superior box quality, improving the overall aesthetics, strength, and functionality of the packaging. The integration of touchscreen interfaces and user-friendly programming enables operators to easily set up and monitor the machine, minimizing the risk of errors and enhancing production efficiency. These technological advancements ultimately redefine the packaging industry's standards, facilitating smooth and error-free manufacturing operations.Environmental Sustainability:In line with the growing global focus on sustainable practices, the lock bottom folder gluer machine offers eco-friendly features. The machine incorporates energy-efficient systems, reducing power consumption and environmental impact. The precise glue application and minimized material wastage also contribute to sustainability efforts by reducing resource consumption. In this way, the lock bottom folder gluer machine supports packaging companies in meeting their corporate social responsibility goals while delivering high-quality packaging solutions.Conclusion:The lock bottom folder gluer machine has revolutionized the packaging industry, offering enhanced productivity, versatile designs, cost-efficiency, advanced technology integration, and environmental sustainability. With its ability to automate the folding and gluing process, this innovative machine ensures increased production rates, consistent box quality, and reduced labor costs. As packaging companies strive to provide efficient solutions that meet customers' evolving needs, the lock bottom folder gluer machine proves to be an indispensable tool in their operations. Embracing this cutting-edge technology enables companies to gain a competitive edge in the dynamic packaging industry, setting new benchmarks for packaging quality and efficiency.

How to Choose the Best Screen Printing Machine for Your Business

Silk Screen Printing Machine Revolutionizes the Printing IndustryIn a world driven by technology and innovation, the printing industry has been no exception to the evolution. As demands for high quality and efficient printing continue to rise, companies are constantly looking for state-of-the-art machinery to meet their production needs. One such breakthrough technology that has taken the industry by storm is the Silk Screen Printing Machine.The Silk Screen Printing Machine, developed by a leading global manufacturer, has revolutionized the printing industry with its cutting-edge features and exceptional performance. This advanced piece of equipment boasts a range of functionalities that allow businesses to print vibrant designs on various materials, from fabrics and plastics to ceramics and metals.With its user-friendly interface and intuitive controls, the Silk Screen Printing Machine simplifies the printing process, allowing even inexperienced operators to achieve professional-grade results. The machine's precision and accuracy ensure that each print is flawless, meeting the highest industry standards. This not only saves time and resources but also enhances the overall quality and aesthetics of the printed products.One of the key features that sets the Silk Screen Printing Machine apart is its versatility. It can accommodate printing on a wide range of materials, making it an ideal choice for businesses in various industries, such as textiles, automotive, promotional products, and electronics. Whether it's creating intricate patterns on t-shirts or printing intricate designs on electronic circuit boards, this machine has the capability to handle it all.Furthermore, the Silk Screen Printing Machine offers unmatched speed and productivity, making it a preferred choice for companies with high-volume printing requirements. Its state-of-the-art technology ensures quick setup times, efficient production, and minimal downtime. This not only increases operational efficiency but also maximizes profitability for businesses.In addition to its impressive capabilities, the Silk Screen Printing Machine also prioritizes sustainability. It incorporates eco-friendly features that minimize energy consumption and reduce waste generation. By utilizing advanced printing techniques, companies can efficiently utilize resources and contribute to a greener future.The company behind this game-changing technology has been a pioneer in the printing industry for over two decades. With a strong focus on research and development, they have consistently introduced innovative solutions that have set new industry standards. As a global leader, their commitment to excellence is evident in the reliability and performance of their products.With an extensive distribution network spanning across the globe, the company has successfully catered to diverse customer needs. Their dedicated customer support team ensures that businesses receive unparalleled service and assistance throughout the entire printing process. From installation and training to ongoing maintenance and troubleshooting, the company is committed to delivering exceptional customer experiences.As the demand for high-quality printing continues to grow, the Silk Screen Printing Machine has become a game-changer in the industry. Its advanced features, versatility, and commitment to sustainability have made it the go-to choice for businesses worldwide. With innovative technologies like these, the printing industry is poised for a future of limitless possibilities.In conclusion, the Silk Screen Printing Machine, developed by a leading global manufacturer, has transformed the printing industry with its groundbreaking features and unparalleled performance. With its versatility, speed, and sustainability, this advanced technology is redefining the way businesses approach printing. As the industry continues to evolve, it is innovations like the Silk Screen Printing Machine that will shape its future.

Impressive IR Dryer Tunnel and Paper Stacking Machine Revolutionize Industry Standards

In the world of manufacturing, efficiency and productivity are key. There is a constant drive to improve processes and reduce production times in order to stay competitive. This is where the IR dryer tunnel and paper stacking machine come in, offering a solution to the challenges faced by manufacturers.The IR dryer tunnel is a piece of equipment used to dry materials after they have been printed or coated. It uses infrared radiation to rapidly heat the material and evaporate the solvents, leaving a dry surface. This is particularly useful in industries such as packaging and printing, where high-speed printing or coating is required. The dryer tunnel can reduce the time needed to dry materials by up to 80%, greatly improving production efficiency.The paper stacking machine is another useful piece of equipment for manufacturers. It is used to stack sheets of paper or other materials into neat piles, ready for packaging or further processing. This may seem like a simple task, but it is one that can be time-consuming and prone to errors if done manually. The paper stacking machine can handle large volumes of material and stack them quickly and accurately, reducing the need for manual labor and improving production times.One company at the forefront of manufacturing technology is a leading manufacturer of these types of equipment. They have years of experience in the field and are dedicated to providing high-quality solutions to their clients. Their IR dryer tunnel and paper stacking machine are just two of the many pieces of equipment they offer, all designed to improve productivity and efficiency in manufacturing.The company has a team of highly skilled engineers and technicians who are constantly working to improve their products. They use the latest technology and materials to create reliable, durable equipment that can withstand the demands of a busy manufacturing environment. Their commitment to quality is evident in their ISO 9001 certification, which ensures that their products meet the highest standards of performance and safety.Their IR dryer tunnel and paper stacking machine are designed to be user-friendly and easy to operate. They can be customized to meet the specific needs of each client, ensuring that they get the most out of their equipment. The company also provides comprehensive training and technical support to their clients, ensuring that they are able to make full use of their equipment and maximize their productivity.The IR dryer tunnel and paper stacking machine are just two examples of the innovative solutions offered by this leading manufacturer. They also offer a range of other equipment, including laminators, embossing machines, and label printing machines. All of their products are designed to meet the needs of a variety of industries, including packaging, printing, and textiles.In conclusion, the IR dryer tunnel and paper stacking machine represent a significant step forward in manufacturing technology. They offer a solution to the challenges faced by manufacturers, improving productivity and reducing production times. The leading manufacturer of this equipment has a track record of providing high-quality, reliable solutions to their clients, and is dedicated to continuous improvement. With their focus on quality, innovation, and customer satisfaction, this company is sure to remain at the forefront of manufacturing technology for years to come.

Revolutionary New Folding Machine Unveiled, Set to Transform Industries

Title: Cutting-Edge Folding Technology Revolutionizes Industrial EfficiencySubtitle: [Company Name]'s Innovative Folding Machine Paves the Way for Manufacturing ExcellenceDate: [Insert Date][City, State] - [Company Name], a leading force in the manufacturing industry, has unveiled its groundbreaking folding machine, promising to transform industrial production lines and exponentially increase operational efficiency for businesses across various sectors. Combining ease-of-use with superior performance, this cutting-edge solution is set to revolutionize the way products are manufactured and packaged.With ever-increasing demands for fast and accurate folding operations, [Company Name]'s folding machine sets a new industry standard, significantly reducing production times while maintaining impeccable precision. Equipped with advanced automation features, this state-of-the-art equipment eliminates human error and delivers consistent high-quality folding results, boosting productivity and profitability.[Company Name], with its rich history of innovation and client-centric approach, understands the challenges that manufacturers face in today's competitive market. The introduction of this folding machine reflects the company's commitment to empowering businesses by providing practical and efficient solutions. Key Features and Benefits:1. Exceptional Precision: Built with cutting-edge technology, the folding machine ensures precise and accurate folding, eliminating even the slightest variations. This level of precision enhances product quality and reduces rejection rates, resulting in significant cost savings for manufacturers.2. Rapid Folding Speed: The machine's high-speed folding capabilities offer unmatched efficiency, enabling manufacturers to meet demanding production schedules with ease. With a remarkable folding speed and a quick setup process, businesses can streamline operations and achieve higher output volumes.3. Versatile Design: The folding machine's adaptable design enables it to handle a wide range of materials and product sizes, presenting a versatile solution for diverse manufacturing needs. This flexibility allows manufacturers to seamlessly transition between product lines without the need for extensive recalibration, enhancing overall production agility.4. User-Friendly Interface: [Company Name]'s focus on user experience is apparent in the folding machine's intuitive interface. With a user-friendly touch panel and simplified controls, operators can easily navigate and program the machine, minimizing training time and enhancing operational efficiency.5. Automated Adjustment: The machine's automated adjustment capabilities eliminate the need for manual intervention between production runs, further streamlining operations and reducing downtime. Once a specific folding pattern is programmed, the machine effortlessly adjusts all settings accordingly, allowing operators to focus on other crucial tasks.6. Space-Efficient Design: [Company Name]'s folding machine boasts a compact footprint, making it ideal for manufacturing facilities of all sizes. The space-efficient design optimizes factory floor space utilization and allows manufacturers to maximize output while minimizing overall footprint.The launch of this revolutionary folding machine has received widespread acclaim from industry experts and manufacturers alike. It is anticipated that this groundbreaking technology will redefine production and packaging processes across multiple industries, including textile, automotive, consumer electronics, pharmaceuticals, and more.As businesses continue to seek innovative solutions that optimize every aspect of their operations, [Company Name]'s folding machine positions itself as an indispensable tool that can accelerate production while ensuring consistently high-quality output. By minimizing human error, reducing lead times, and adapting to various manufacturing requirements, [Company Name]'s folding machine sets new benchmarks in efficiency, reliability, and productivity.[Company Name] continues to strive for excellence, constantly pushing the boundaries of innovation. Through their newest product, they reaffirm their commitment to helping manufacturers unlock their full potential, providing solutions that not only streamline operations but also lay the foundation for future growth and success.About [Company Name]:[Company Name] is a leading provider of cutting-edge manufacturing solutions, dedicated to delivering high-performance equipment tailored to meet the unique needs of businesses worldwide. With a focus on innovation, quality, and customer satisfaction, [Company Name] has established itself as a trusted partner in manufacturing excellence.For more information about [Company Name] and their revolutionary folding machine, please visit their website at [insert website].

Unlocking the Power of Screen Printing: A Comprehensive Guide

A leading screen printer in the UK, with a reputation for quality and excellence, is celebrating its latest business milestone as it continues to grow and expand its operations.The company, which specialises in high-quality screen printing and embroidery services for a wide range of clients across the UK, has just announced the purchase of a brand-new state-of-the-art printing machine that will enable them to handle even larger orders with greater speed and efficiency.The growth of the business reflects a trend towards increased demand for customised apparel, as more and more companies seek to differentiate their branding and enhance their marketing efforts with branded merchandise.Established over a decade ago, the company has built a reputation for quality and reliability, thanks to its skilled team of expert technicians who are all highly experienced in the screen printing process.Using the latest technology and top-quality materials, the screen printing and embroidery services provided by the company allow clients to create customised designs that are tailored to their exact specifications.With a commitment to quality and excellence that is second to none, the company has established itself as a leader in the field of screen printing and embroidery services. Their ability to produce high-quality, customised designs at scale has seen them gain a loyal following of clients across a diverse range of industries, including fashion, sports, retail, and corporate branding.The purchase of the new state-of-the-art printing machine is part of the company's ongoing commitment to investing in the latest technology and equipment, ensuring that they remain at the forefront of their industry and can continue to offer their customers the very best service and quality.Commenting on the purchase of the new machine, the company's director said, "We are thrilled to be able to add this fantastic new piece of equipment to our arsenal. It will enable us to handle even larger orders with speed and efficiency, while still maintaining the high quality and attention to detail that our clients have come to expect from us."The director went on to add, "At our core, we are a company that is committed to providing the very best screen printing and embroidery services to our clients. We believe that this investment in the latest technology and equipment will help us to grow and expand our operations, while also maintaining our reputation for quality and excellence."With the new printer now installed and ready to use, the company is looking forward to expanding its customer base and taking on even bigger and more challenging orders. Whether it is customised t-shirts, hats, or even personalised apparel and merchandise, the team at this leading screen printer is well-equipped to deliver the very best in quality and value for its customers. So, if you are looking for high-quality, customised screen printing or embroidery services, look no further than this leading UK screen printer – a company that is committed to excellence, customer satisfaction, and continuous improvement.

Latest Innovation in Packaging Technology: Crash Lock Box Folder Gluer Provides Efficient Solutions

Shanghai, China - In response to the growing demand for efficient and high-quality packaging solutions, a leading packaging machinery manufacturer has launched the latest Crash Lock Box Folder Gluer. The new machine is specifically designed to cater to the needs of small and medium-sized packaging companies that are seeking to enhance their productivity and output while maintaining affordability.The Crash Lock Box Folder Gluer is a state-of-the-art machine that is suitable for folding and gluing various types of boxes, including, but not limited to, corrugated boxes, flat boxes, and box envelopes. The machine is highly versatile, and its flexibility in terms of size and format makes it the perfect choice for companies looking to produce a broad range of products for different markets.In addition to its versatility, the Crash Lock Box Folder Gluer is designed to offer top-level efficiency. With its highly automated features, the machine helps you increase productivity and reduce labor costs significantly. The machine's computerized control system ensures that every stage of the process is handled accurately and optimally, saving you time and resources while producing high-quality products that meet your customers' demands.One of the key aspects that set the Crash Lock Box Folder Gluer apart from its competitors is its compactness. Unlike many other folding and gluing machines, this machine is designed to occupy less space, making it an ideal option for small to mid-sized companies that have limited space. Despite its compact nature, the machine packs a punch in terms of output and functionality, making it highly efficient and reliable.The Crash Lock Box Folder Gluer is manufactured by a leading supplier of packaging machinery in China. The company has been in the packaging industry for over a decade, and its expertise and experience are embodied in the many products it has successfully launched over the years. The company focuses on product quality, efficiency, affordability, and reliability, ensuring that its customers are always satisfied with their purchases."We are excited to launch the newest addition to our line of packaging machinery," said the CEO of the manufacturing company. "The Crash Lock Box Folder Gluer is designed to meet the ever-increasing demand for efficient and high-quality packaging solutions. With its compact design and automated features, we are confident that it will revolutionize the way small and medium-sized packaging companies work."The Crash Lock Box Folder Gluer comes with a one-year warranty, and the company offers comprehensive after-sales and maintenance services to ensure that customers get the most out of their investment. The machine is easy to operate, and the manufacturer provides training and technical support to all customers to ensure that they can maximize their usage of the machine.In conclusion, the Crash Lock Box Folder Gluer is an innovative packaging solution that is poised to transform the packaging industry. With its versatility, efficiency, affordability, and reliability, it is the perfect machine for small and medium-sized packaging companies that seek to increase productivity, reduce labor cost, and meet their customers' varying demands. The manufacturer has once again demonstrated its commitment to customer satisfaction by launching a product that embodies quality and function.